3. Durability Through Design: How Lines Contribute to Durability

The design of a towel, including the lines, plays a significant role in its durability. The lines act as reinforcement points, distributing stress and reducing the risk of tearing. This is especially beneficial for high-quality towels, where the lines are precisely woven to ensure even stress distribution.

Furthermore, the lines help the towel maintain its shape over time. Towels without lines are more susceptible to stretching and losing their shape, especially after repeated use and washing. The lines create a frame that helps the towel maintain its original dimensions, ensuring its functionality and aesthetic appeal for longer.

4. Aesthetics: The Visual Impact of Lines on Towels

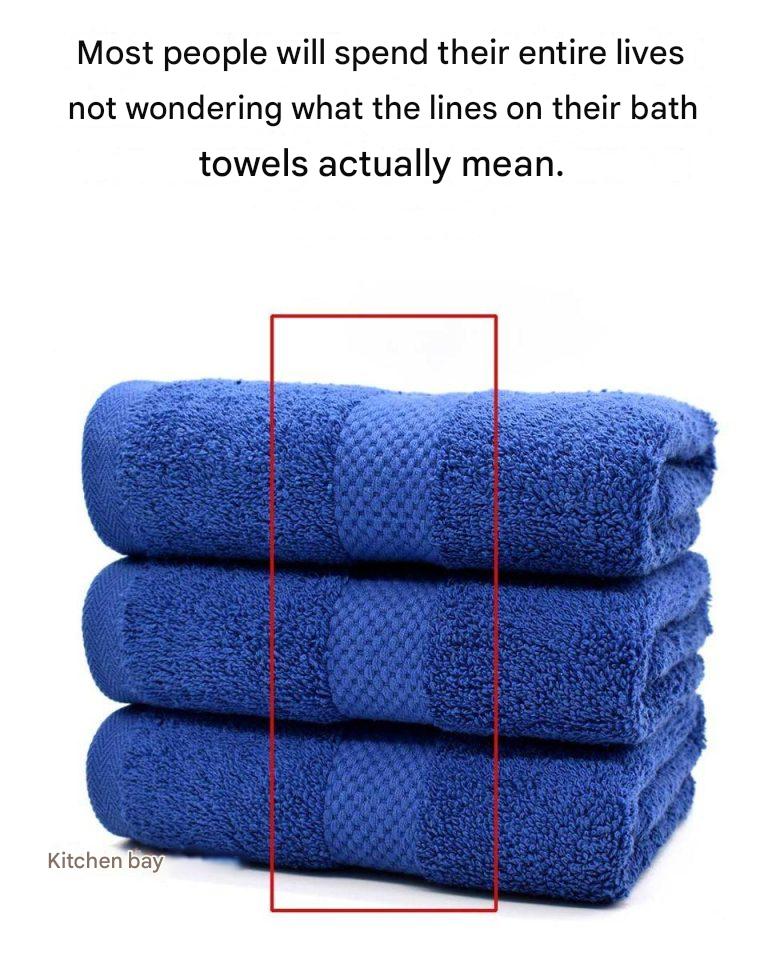

Beyond their functional benefits, the lines on bath towels also contribute to their aesthetic appeal. Lines can be used to create intricate patterns and motifs, adding a touch of elegance to a simple item. These patterns can range from simple stripes to complex geometric shapes, depending on the weaving technique used.

The visual impact of these lines can also influence consumer preferences. Towels with well-designed lines are often perceived as more luxurious and upscale, making them a popular choice for those looking to add a touch of sophistication to their bathroom décor. Lines can also be used to complement other bathroom design elements, creating a cohesive and stylish look.

5. Table Runner Weaving: Explaining the Weaving Technique

Table runs are created using a special weaving technique known as “table runner weaving.” This technique involves alternating tension between the warp and weft threads, creating raised lines on the fabric’s surface. This process requires precision and skill, as the lines must be evenly spaced and of uniform depth to ensure the towel’s functionality.

The tread weaving technique is often used in conjunction with other weaving methods, such as dobby weave, to create towels with complex patterns and increased absorbency. The resulting fabric is not only functional but also visually appealing, making it a popular choice for producing high-quality bath towels.

6. Understanding Dobby Weave

Dobby weave is a popular technique for creating lines on bath towels. This weaving method involves using a dobby loom, which allows for the creation of fine, geometric patterns. Dobby weave is ideal for creating intricate patterns, as it allows for a variety of textures and patterns on the fabric’s surface.

Dobby weave is particularly effective in increasing the towel’s absorbency and durability. The patterns created by dobby weave increase the surface area of the towel, allowing it to absorb more moisture. Furthermore, the weave structure strengthens the fabric, making it more resistant to wear. This combination of functionality and aesthetics makes the dobby weave a popular choice for high-quality bath towels.

7. How do weaving techniques affect towel durability?

The durability of a towel is largely influenced by the weaving techniques used in its production. Techniques such as the tread weave and dobby weave create lines that reinforce the fabric, making it more durable and resistant to damage. These techniques ensure that the towel will withstand repeated use and washing without losing its shape or functionality.

Furthermore, the quality of the yarn used in these weaving techniques also affects the towel’s durability. High-quality yarns, such as Egyptian or Turkish cotton, are often used in conjunction with advanced weaving techniques to create towels that are not only durable but also soft and luxurious. This combination of high-quality materials and expert craftsmanship ensures that the towel will remain in excellent condition for years to come.

8. Environmental Impact of Towel Production

The production of bath towels has a significant environmental impact, particularly in terms of water and energy consumption. The weaving techniques used to create the patterns on towels require large amounts of water and energy, contributing to the overall carbon footprint of towel production. However, technological advancements have led to more sustainable production methods, reducing the environmental impact of towel production.

Many manufacturers now adopt environmentally friendly practices, such as using organic cotton and implementing water-saving technologies in their production processes. These practices not only reduce the environmental impact of towel production but also translate into higher-quality products that are better for both consumers and the planet.

9. Comparing Different Towel Materials

The material used to produce a towel has a significant impact on its performance and comfort. Cotton is the most commonly used material in towel production, with Egyptian and Turkish cotton being the most sought-after due to their excellent absorbency and softness. These materials are often used in conjunction with advanced weaving techniques to create high-quality towels with enhanced functionality.

Besides cotton, other materials such as bamboo and microfiber are also used in towel production. Bamboo towels are known for their environmental friendliness and natural antibacterial properties, while microfiber towels are lightweight and quick-drying. Each material has its own unique advantages, making it important for consumers to consider their specific needs when choosing a towel.

10. Innovations in Towel Design

CONTINUE READING ON THE NEXT PAGE 🥰💕