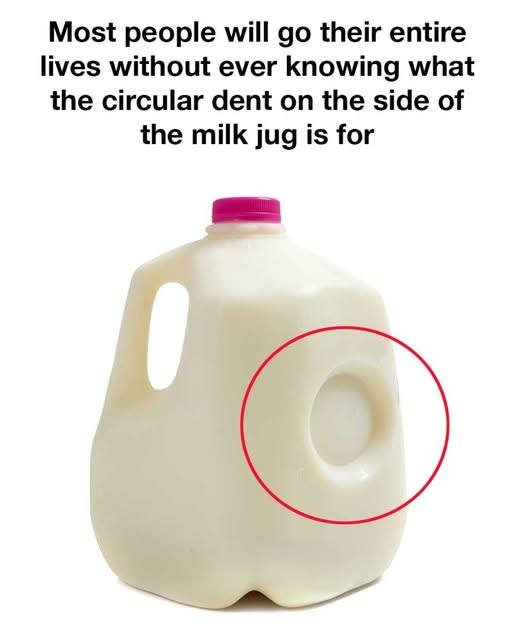

The Circular Dent on Milk Jugs: A Small Design Feature with Big Benefits

Every time you pick up a plastic milk jug, you’ll notice a small, circular indentation on its side—yet most of us pay it no mind. Far from a mere manufacturing quirk, this subtle dent is a carefully engineered feature that enhances the jug’s performance, safety, and sustainability. Here’s why that little circle matters.

1. Structural Integrity and Pressure Management

Plastic milk jugs must withstand both the weight of the liquid they carry and the temperature fluctuations of storage and transport. The circular dent acts as a built‑in “flex point,” allowing the jug to expand slightly under internal pressure—without cracking. Whether exposed to a hot delivery truck in summer or a cold fridge in winter, the dent releases stress and preserves the jug’s shape.

2. Cost‑Effective Material Use

Adding strength through shape rather than bulk means manufacturers can use less plastic overall. The dent reinforces the jug’s wall like an architectural arch, reducing raw‑material costs and lowering environmental impact. By optimizing material use, producers save on expenses and contribute to less plastic consumption.

3. Improved Consumer Safety

Accidents happen, and a dropped jug can easily puncture or split. That circular groove absorbs and redirects impact, reducing the likelihood of a sudden rupture. In busy households—especially those with children—this design helps prevent messy spills and potential injury, ensuring milk stays safely contained.

4. Easier Recycling and Reduced Waste

CONTINUE READING ON THE NEXT PAGE 🥰💕